SKU: MX101-SM

The Aaron | 3 inch Architectural Exterior Trim & Premium Foamcore Moulding

The Aaron is a precise 3-inch architectural trim engineered for Universal Substrate Compatibility. Whether your project features Stucco (EIFS), Brick, Stone Veneer, ICF, or Concrete, The Aaron provides a seamless, rock-hard masonry finish without the structural weight.

Proven over 25 years, our lightweight moulding system eliminates the 0.00003 thermal expansion gaps found in PVC, the moisture rot common in Wood/MDF and the heavy weight of pre-cast making it the definitive choice for any exterior elevation.

6 inch Sample - Free Shipping

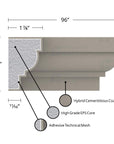

Lightweight, high-density EPS foamcore, wrapped in an alkali-resistant fiberglass mesh with a proprietary polymer-modified cement finish, engineered for zero-joint expansion and 100% moisture resistance.

Height: 3 inches | Depth: 1-7/8 inches | Bottom: 3/8 inches

Price per 8' Length: $34.16

Price per foot: $4.27

Watch Installation Video

Core Material: High-density expanded polystyrene (EPS) core protected by a proprietary polymer-modified cementitious coating (approx. 3/16 inch thick).

Thermal Stability: Engineered for zero-gap joint integrity; thermal expansion coefficient optimized to resist shrinking or cracking during extreme North American freeze-thaw cycles.

Bonding Technology: Bond ready surface optimized for high-strength architectural masonry adhesives; compatible with EIFS, brick, stucco, and stone substrates.

Weight & Structure: 90% lighter than traditional pre-cast concrete (approx. 1/10th the weight), eliminating the need for heavy-duty structural wall reinforcement or mechanical hoisting.

Finishing Options: Arrives in a uniform cement-gray finish that acts as a premium masonry primer; compatible with all high-quality exterior acrylic latex paints and textures.

Technical Customization: Precision factory-cut to any architectural profile; capable of achieving true arches, ellipticals, and bespoke geometric shapes that traditional materials cannot replicate.

Environmental Durability: 100% inorganic and inert; naturally resistant to moisture, wood-boring insects, rot, and UV degradation for a maintenance-free lifecycle.

DESIGNER'S SUGGESTED STYLE KIT

Mouldex Exterior Mouldings vs Alternatives

| Criteria | MOULDEX EXTERIOR | AZEK / PVC | PRE-CAST | WOOD / MDF |

|---|---|---|---|---|

| Moisture & Rot | 100% Inorganic / Proof | Proof | Absorbent (Spalling) | Poor (Swelling/Rot) |

| Thermal Stability | Near-Zero Expansion | High (Joint Separation) | Low / Brittle | Moderate (Warping) |

| Monolithic Sizing | One Piece (Up to 42 inches) | Requires Assembly | Limited by Weight | Requires Assembly |

| Custom Shape | Quick & Cost Effective | Not Available | Expensive & Slow | High Cost & Slow |

| Install Weight | Ultra-Lightweight | Lightweight | Extreme (Cranes) | Medium (Heavy) |

The 6 Pillars of Evolved Foamcore Technology

Mouldex Exterior Mouldings Engineering & Performance

Exterior architectural mouldings, whether used for window trim, sills, or cornices, play a dual role in both aesthetic enhancement and building protection. At Mouldex, we manufacture a proprietary cement coated foamcore solution designed to solve the inherent failures of traditional masonry and wood materials.

1. The Evolution of Foamcore

Mouldex profiles represent a generational leap in material science. We utilize a High-Density Expanded Polystyrene (EPS) core, wrapped in an alkali-resistant fiberglass mesh and encapsulated in a proprietary polymer-modified cement shield. This creates an inorganic, durbale exterior that is 100% moisture-proof and impact-resistant, engineered to outperform traditional foamcore, pre-cast, wood/MDF, and PVC.

2. Versatile Substrate Compatibility

Unlike traditional trims designed for a single wall type, Mouldex is engineered for Universal Compatibility. Our adhesive-based bonding technology is optimized for a permanent, structural hold on Brick, Stone, Stucco, Vinyl/Siding, and ICF. This eliminates the 0.00003 thermal expansion gaps found in PVC and the moisture rot common in Wood and MDF.

3. Unmatched Customization & Arches

Where rigid materials like PVC and wood fail, Mouldex excels. Our Bespoke Customization allows us to manufacture precision-cut Arches, Full Circles, Ovals, and Ellipticals to match any architectural radius. Utilizing advanced CNC technology, we can replicate historical profiles or create modern shapes with a 7–10 days.

4. Timestone Look Without the Weight

Traditional pre-cast concrete requires expensive structural reinforcement and heavy machinery. Mouldex provides an indistinguishable masonry aesthetic at 1/10th the weight. This Weight Efficiency eliminates the need for cranes or wall-load upgrades, typically providing a 75% total cost savings over stonecast products.

5. Engineered for Freeze-Thaw Cycles

Our proprietary coating is the definitive choice for the Northern US and Canadian climates. While GFRC and fiberglass alternatives often crack under thermal stress, Mouldex is engineered for Zero-Joint Expansion, maintaining its structural integrity through extreme temperature swings.

6. Pro-Grade, Fast-Track Installation

Our Nail-less Installation system utilizes high-bond architectural masonry adhesives. This prevents the building envelope from being compromised by thousands of nail holes and eliminates the risk of rusting fasteners bleeding through your finish over time. For larger shapes, we utilize a rear attachment mechanism for stability and safety.